Lightweight EV Battery Pack - South Korea

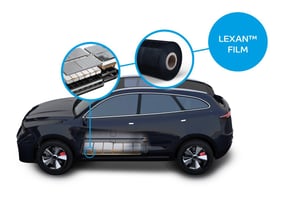

Lightweight and Compliant EV Battery Pack with LEXAN™ EFR95 Film

To produce a slim and lightweight EV battery pack system, Boback CNS has engineered a state-of-the-art roll-to-sheet thermoforming machine. With this cutting-edge technology, it is possible to produce mass quantities of insulation sheets, which meet the environmental guidelines and high standards of electrical and mechanical properties from EV battery manufacturers.

INDUSTRY STANDARDS:

- RoHS-REACH compliant

- Dielectric strength

- Flame retardant

- Resistance to chemicals (CTI)

PRODUCT SOLUTION:

LEXAN™ EFR95 film in 0.43mm can be used in EV battery module covers, thermoformed and fabricated with patented processes to solve the OEM's demanding requirements like weight reduction and design freedom.

INDUSTRY STANDARDS:

- RoHS-REACH compliant

- Dielectric strength

- Flame retardant

- Resistance to chemicals (CTI)

PRODUCT SOLUTION:

LEXAN™ EFR95 film in 0.43mm can be used in EV battery module covers, thermoformed and fabricated with patented processes to solve the OEM's demanding requirements like weight reduction and design freedom.

{{ sectionTitle }}

{{ sectionTitle }}

|

{{getTranslation(col)}}

|

|---|

|

{{row[col]}}

{{row[col]}}

|

No resources available.

Distributor or Partner:

Boback CNS enhanced their mass-production capability to 3D formed insulation sheet to meet the growing demands from Electrical Vehicle (EV) Battery Original Equipment Manufacturers (OEMs) by using LEXAN™ EFR film. This in-line forming system not only reinforces their commitment to meeting industry requirements but also signifies their dedication to delivering innovative solutions that align seamlessly with the evolving needs of electric mobility